Development of Environmentally Sustainable Products

Tsuneishi Shipbuilding is developing eco-friendly ships using cutting-edge technologies to reduce GHG emissions. Currently, all of our major ship types have accomplished Phase 3 of the Energy Efficiency Design Index (EEDI) to prove their high fuel effiency and environmental performance. We will continue to develop measures and technologies that are geared towards the realization of a carbon-free society.

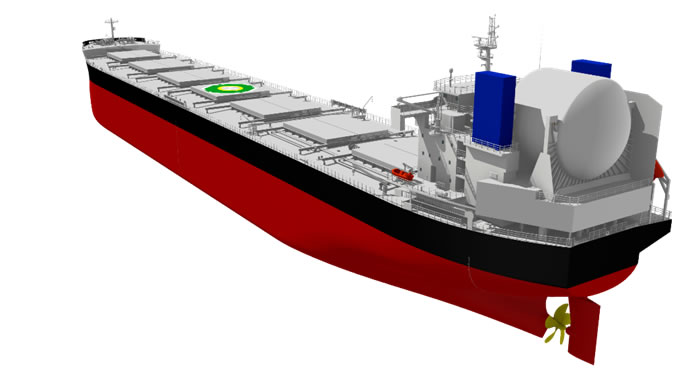

Our “KAMSARMAX GF”, a dual fuel-fired bulk carreer of LNG and heavy oil, has obtained basic design approval of the Approval in Principle (AIP) from the Lloyd’s Register of Ships in April 2021. The ‘GF’ of “KAMSARMAX GF” stands for ‘Gas Fuel’, signifying that the ship is eco-friendly and versatile with higher environmental performance of LNG fuel usage.

▷ Link to product information of Tsuneishi Shipbuilding (Click here for more details)

▷ Link to Technical Information of Tsuneishi Shipbuilding (Click here for more details)

Methanol-fueled KAMSARMAX bulk carrier order

KAMSARMAX is a newly developed dual-fuel bulk carrier using methanol and conventional heavy fuel oil. Equipped with an independent large-capacity methanol fuel tank, it ensures sufficient cruising range with the use of both methanol and heavy oil. Moreover, in addition to the significant enhancement in fuel efficiency due to the hull shape improvement, compared to the conventional KAMSARMAX design, Tsuneishi Shipbuilding applied upgraded version of “AEROLINE”*2, our unique wind resistance reduction technology applied to TESS 64/66 series, to KAMSARMAX for the first time. We are striving to improve actual shipping performance by reducing wind resistance.

The stern placement of the simply structured methanol fuel tank is to maintain the large cargo hold capacity which characterizes KAMSARMAX while ensuring the safety and ease of cargo handling, realizing the safe and efficient maintenance by crew.

With most of the principal particulars and specifications of the KAMSARMAX, the vessel also features high versatility.

We will continue to accelerate the research and development of next-generation vessels fueled by not only methanol but also ammonia and hydrogen, and strive to contribute to mitigating the load to the global environment by providing customers with zero-emission ships that achieve both environmental performance and economic efficiency.

*1 AEROLINE:

TSUNEISHI SHIPBUILDING’s proprietary technology that reduces wind resistance by approximately 20% by streamlining the bow and accommodation space.