Topics

The 10th Anniversary of academic-industrial cooperation between Tsuneishi Shipbuilding Co., Ltd. and the Engineering Research Department of Hiroshima University Graduate School. Many innovations in applied technology have been made to increase value in the field of shipbuilding.

May 23, 2014

On April 30th, 2014, Tsuneishi Shipbuilding Co., Ltd. (Headquarters: Fukuyama City, Hiroshima Prefecture) held a debriefing meeting about cooperative research with the Engineering Research Department of Hiroshima University Graduate School in 2013, at Tsuneishi factory headquarters. This cooperation has continued for 10 years since we concluded a comprehensive research cooperation agreement, aiming to develop technologies for ship design and environmental conservation. In the past, most of our research results led to enhancements in thrust performance, safety, and environmental efficiency during the building of new ships.

- ■Tsuneishi Shipbuilding Co. Ltd.

- http://www.tsuneishi.co.jp/english/index.shtml

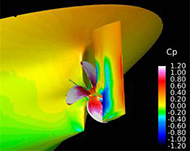

Tsuneishi Shipbuilding Company and Hiroshima University are conducting research activities in 4 fields; performance, structure, outfitting, and environment. So far, we have conducted research activities on 57 themes over 10 years. For this research, we have used facilities and experiment equipments including Hiroshima University’s 110-meter model experimental pool, wind-channel test equipment, and a CFD simulation calculation tool. About 22 professors from the fields of hydrodynamics, structural dynamics, and oceanography which are directly related to shipping concerns, as well as architecture and ergonomics, have conducted research activities with Tsuneishi Shipbuilding Company staff.

|

Based on the results of this research, we developed a new bow shape design which resists wave pressure as well as corner cutoff shape in an accommodation space and additions which resist wind pressure to improve fuel consumption. We have also developed a new propellor design and steering with high-efficiency and energy saving performance by transmitting the main engine energy into thrust force, and a safer hull structure by enhancing the strength using topology optimization methods (optimized shape design method). These technologies have been serially introduced to Tsuneishi Shipbuilding Group’s ships. Additionally, our thesis about the resonance phenomenon caused by anchor chain vibration won the 2012 award by The Japan Society of Naval Architects and Ocean Engineers. In this way, we are making scholarly contributions to the field of marine studies as well as to applied technology. In response to recent increased concern about enhancement of crew work environments, we’re planning to expand the field of our research to cover efficient and safe shipbuilding methods and noise control/air conditioning in an accommodation space. Based on our research results, we aim to realize innovative ideas new to the shipbuilding industry. |

|

Professor Hiroki Yasukawa at the Engineering Research Department of Hiroshima University Graduate School, which co-manages the comprehensive research cooperation system between Tsuneishi Shipbuilding and Hiroshima University comments, “Over these last 10 years, we’ve made many research results by combining Tsuneishi Shipbuilding’s research needs with Hiroshima University’s research functions, and by discussion and close cooperation together In the future, we’d like Tsuneishi Shipbuilding to utilize our educational functions for their human resource training because that’s one of the major missions for Universities. Also, we’d like to establish a closer system of cooperation, introducing new input and new points of view, such as cooperation with overseas research organizations, following Tsuneishi Shipbuilding’s global business.” Shi Jiangang, Assistant Manager for the Product Planning Department, Design Division, Tsuneishi Shipbuilding said, “Many cooperative research results by Tsuneishi Shipbuilding and Hiroshima University have been introduced to the ships. We are contributing to increased customer value including realizing energy-conserving ships. We’d like to establish our products superiority in this stiff global competition by taking initiative in the shipbuilding industry in terms of introducing new technologies.”