Press Releases

First external “supplemental machine heat collecting unit” for ships in the shipbuilding industry is now on sale.

July 2, 2013

Tsuneishi Shipbuilding Co., Ltd. (Headquarters: Fukuyama city, Hiroshima CEO: Takao Kawamoto) and Miura Co., Ltd. (Headquarters: Matsuyama city, Ehime CEO: Yuji Takahashi) have co-developed the shipbuilding industry’s first*1 external “generator engine waste heat recovery unit” (patent pending). “Generator Engine Waste Heat Recovery Unit” allows collection of exhaust heat from the generator engine equipped in the ship as a heat resource. The unit converts the heat to energy for the auxiliary boiler and can reduce the auxiliary boiler’s fuel consumption by 12-25 %.

Originally, the heat resources aboard the ship used exhaust heat from the main engine. But as efforts to reduce exhaust CO and NOx have lowered the temperature of exhaust from the main engine, it has become difficult to obtain the required energy. Additionally, the exhaust heat of an onboard generator engine inside the ship has less energy than the main engine. Therefore this couldn’t be put to effective use either.

and NOx have lowered the temperature of exhaust from the main engine, it has become difficult to obtain the required energy. Additionally, the exhaust heat of an onboard generator engine inside the ship has less energy than the main engine. Therefore this couldn’t be put to effective use either.

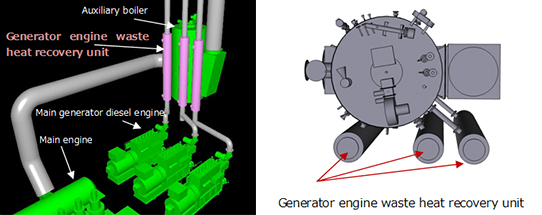

The “Generator Engine Waste Heat Recovery Unit” which has now been developed can be installed to the respective generator engines to connect to a main engine’s auxiliary boiler which used to be the exhaust machine heat collecting unit. These new generator engine waste heat recovery unit can collect exhaust heat from multiple generator engines efficiently and complement the main engine’s utilization of exhaust heat.

Tsuneishi Shipbuilding Co., Ltd. has already decided to introduce this “generator engine waste heat recovery unit” to some ships which will be built after 2014.

【Features】

- In case it is introduced to Tsuneishi Shipbuilding’s ship, the amount of heat collected from generator engines will be about 10% of the heat collected from the main engine, and about 100kg/h of steam can be generated. Without increasing the size of the auxiliary boiler, it can generate the sufficient amount of steam required to keep inside the ship.

- With the cooperation of Daihatsu Diesel mfg. Co., Ltd. (Headquarters: Osaka City, Osaka Prefecture), a newly developed specialized silencer is also equipped to this unit, helping to decrease the noise heard in the neighborhoods when a ship enters the port.

- Flexible layout is possible so that the maintenance space can be secured for various pipe configurations or machine structures around the generators and the auxiliary boiler.

- To prevent soot from building up in conducting tubes inside the unit, a high pressure air soot blower*2 is installed to each conducting tube.

| *1 | Researched by MIURA Co., Ltd. |

| *2 | This equipment prevents heat conductivity from dropping by blowing compressed air inside the conducting tubes so that soot generated from combustion gas doesn’t build up inside the tubes. |

【Time of sale】

Start sales in fiscal year 2013. Planned to introduce to a newly built ship from fiscal year 2014.

【Main specifications of single generator engine waste heat recovery unit】

| Items | Specifications |

|---|---|

| Heat transmission area | 10.8㎡ |

| Reserved water quantity | 270kg |

| Weight (dried) | 870kg |

| Size | Height: Approx. 5,300mm x Diameter: Approx. 600mm |

| Amount of generated steam | Approx. 100kg/h *In case of Tsuneishi Shipbuilding Company’s ship under 50% load to a generator. |

| Heat exchange type | Fume tube type |

| Feed-water control | Control type: Control water level of the boiler on the main engine side. Circulation type: natural circulation system |

【Arrangement of auxiliary boiler and generator engine waste heat recovery unit】

【Company Information of Miura Co., Ltd.】

| CEO | Yuji Takahashi |

| Headquarters | 7-banch, Horie-cho, Matsuyama city, Ehime Prefecture |

| Establishemt | November, 1959 |

| Number of Employers | 4,086 (Consolidated. As the date of March 31st, 2013) |

| Capital | 9,544,000,000 yen (As the date of March 31st, 2012) |

| Sales amount | 78,157,000,000 yen (Consolidated statement for fiscal year 2013) |

| Main business | Manufacture, sales, and maintenance of the unit including small size through-flow boiler, water treatment system, and cooling unit. |

- Contact for this information -

Tsuneishi Holdings Corporation

Company Communication/CSR Room

Shimizu/TEL: 084-987-4915

Miura Co., Ltd.

Brand Planning Room

TEL:089-979-7019 FAX:089-979-7126

Mail: burandokikakushitsu@miuraz.co.jp